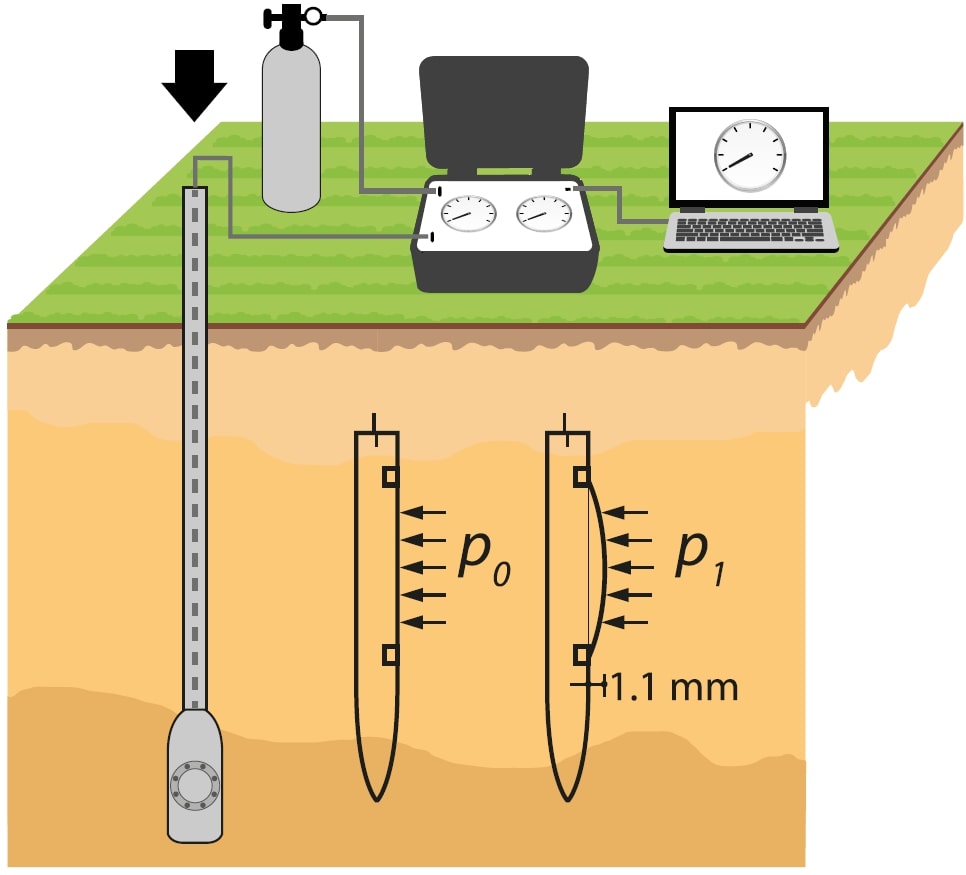

A Flat Dilatometer test consists in advancing a blade into the ground with any common field machine. At each test depth, a circular steel membrane located on one side of the blade is expanded horizontally against the soil. The pressure readings are recorded at specific moments during the membrane expansion. The blade is then advanced to the next test depth, typically with 0.20 m depth interval.

Table of Contents

Add a header to begin generating the table of contents