The Medusa DMT is a probe able to autonomously perform dilatometer tests, which generates and measures the pressure directly at depth. The obtained DMT readings are extremely repeatable, because the fluid is liquid (incompressible) and the pressure regulation is electronically controlled. New test procedures are possible, such as high resolution dissipation tests and horizontal pressure measurements during penetration.

Medusa

Home >

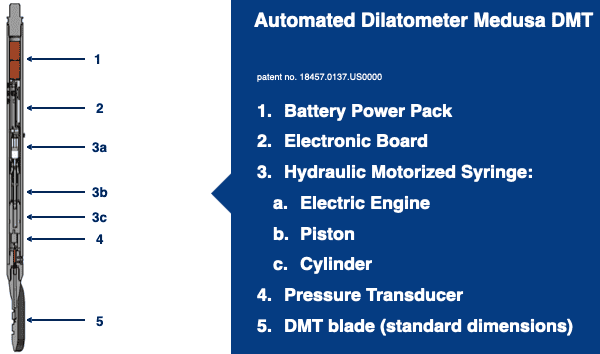

Medusa DMT composition

The figure below shows the main components of the instrument. A rechargeable battery pack powers an electronic board, connected to a pressure transducer and to a custom designed motorized syringe. The firmware coded in the electronics activates the motorized syringe for generating the pressure required to obtain the DMT readings. The maximum operating pressure is 25 MPa. A high accuracy pressure transducer is used to measure the pressure generated by the syringe and operating on the membrane. An electric wire provides the contact status of the membrane to the electronic board. The A, B, C pressure readings are taken by the electronic’s firmware with the same criteria used for the traditional pneumatic DMT equipment.

Medusa DMT cableless

When the Medusa DMT is operated cableless, a programmable period (TMCP) determines when to start each measurement cycle. In the first part of the period, the A, B, C readings are taken and stored in the EPROM memory. The system will then stay in an idle state, waiting for the penetration to the next test depth. A typical period for TMCP is of 1 minute, where the measurements are taken in the first 30 seconds and the device is idle in the remaining seconds for completing the period. During these additional 30 seconds the instrumentation is advanced to the next test depth. The time origin for the synchronization (T = 0) is set with the ON/OFF switch. The USB connection enables to program test parameters, such as TMCP, and to download the data at the end of the test, when the probe is retrieved.

Medusa DMT with cable

The Medusa DMT may also operate with an electric cable running from a computer laptop at ground surface down to the probe at depth. In this configuration, the operator may activate the measurement cycle from the computer as soon as the test depth is reached. During the cycle all automation parameters, such as the battery status, the voltage and current provided to the engine, the position of the piston of the motorized syringe, the probe inclination and other additional information, are available in real time. The DMT parameters, in particular the current pressure and membrane contact status, are displayed in real time during the measurement, as for the traditional DMT pneumatic technology.

For the Medusa DMT the firmware embedded in the electronic board implements the procedure for inflating and deflating the DMT membrane. The hydraulic pressurization of the motorized syringe actuates a volume controlled expansion of the membrane, which enables to impose a programmable timing for achieving the readings. Therefore the Medusa DMT is capable to perform dilatometer tests with the recommended timing suggested in the international standards. At the same time, the highly accurate and repeatable time-for-reading facility provided by the instrument prompts for its potential use for performing dilatometer tests adopting variable pressurization rates in intermediate soils.

The motorized syringe, controlled by the electronic board, is also able to maintain the membrane in equilibrium with negligible displacements of the membrane. This capability enables to obtain continuous measurements of the total horizontal pressure of the soil against the membrane. The Medusa DMT may then be used to obtain continuous measurements of the total horizontal pressure during penetration (equivalent A-reading at T = 0 seconds instead of T = 15 seconds), thus providing useful indications for the assessment of the in-situ stress state and the at-rest lateral earth pressure coefficient (K0).

As in the standard pneumatic DMT, the A, B, C readings must be corrected with the calibration offsets ΔA and ΔB to obtain p0, p1, p2, respectively (Marchetti et al. 2001). All subsequent steps of data processing and interpretation of soil parameters, based on the corrected pressures p0, p1, p2, are the same as for the traditional pneumatic DMT equipment.

Check details on calibration chamber and field validation of the Medusa DMT

Medusa DMT advantages

The Medusa DMT has several advantages over the traditional pneumatic equipment, both in terms of simplification of the probe and test procedure, and in terms of increased accuracy of the measurements (Marchetti et al. 2019). The major advantages are listed here below.

- The overall equipment occupancy is reduced to the size of the standard blade with a rod connected on its top, for a total height of about 1 m. The gas tank, the control unit and the pneumatic cables are no longer required.

- The probe may operate in cableless mode, which is a significant practical advantage, especially in the offshore industry. An optional electric cable may be used for obtaining real-time results during test execution.

- The pressure is generated and measured locally at depth, not at ground surface. This eliminates any possible problem of pressure equalization along the pneumatic cable of the traditional equipment.

- The pressurization rate of the membrane is independent of the operator. The automatic (volume controlled) procedure of membrane pressurization operated by the motorized syringe is highly repeatable and capable to impose the correct timing to obtain the A and B pressure readings, strictly according to the specifications of the international standards or any other required timing.

- The capability of the Medusa DMT of measuring (virtually continuously) the total horizontal pressure against the membrane with time enables new research possibilities.

- Short A-dissipations, consisting in repeated A-readings (without expansion of the membrane from A to B) for a couple of minutes, may be executed to detect intermediate or partially draining soil layers (Marchetti 2015, Marchetti and Monaco 2018). The duration of such short A-dissipations (much shorter than conventional DMT-A dissipation tests that provide the entire A-decay curve) is sufficient to discover whether an appreciable reduction of the total contact pressure A, reflecting pore pressure dissipation, occurs during the test. The Medusa DMT permits to execute routinely short A-dissipations before recording each standard A-reading, which is taken 15 s after reaching the test depth. In clays no appreciable pore pressure dissipation occurs in 15 s and the A-readings remain nearly constant, indicating fully undrained conditions, while a substantial reduction of A in 15 s prompts for partial drainage.