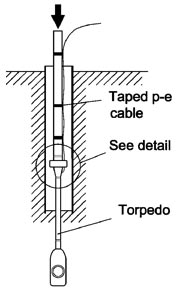

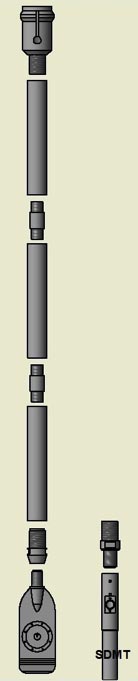

- Lower the torpedo down to the bottom of the hole.

- Push the torpedo and do DMT for 3 m (stopping before the exit of cable reaches the bottom of the hole).

- Extract the torpedo.

- Remove the soil that was penetrated and tested by the blade, thereby advancing the borehole down to the max depth previously reached by the blade.

- Lower the torpedo down to the bottom of the hole and resume testing.

The diameter of the casing of the borehole should be as small as possible, to minimize the risk of buckling (possibly 100 mm ID). The penetration must always occur in “fresh” (not previously penetrated) soil.

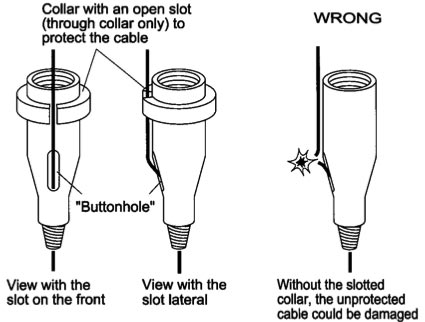

It is generally convenient to use a 4 m long extendable pneumatic-electric cable, connected to the blade and egressing from the upper slotted adaptor. Then normal length pneumatic-electric cable will be attached to the 4 m cable.