The absence of the B-reading is a serious inconvenience. Without B the operator keeps inflating beyond 1.1 m, blowing the membrane.

It is therefore imperative to correct this defect.

There can be two reasons of the missing B:

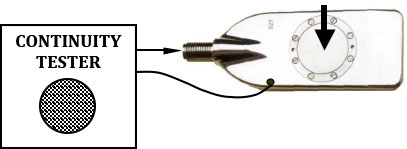

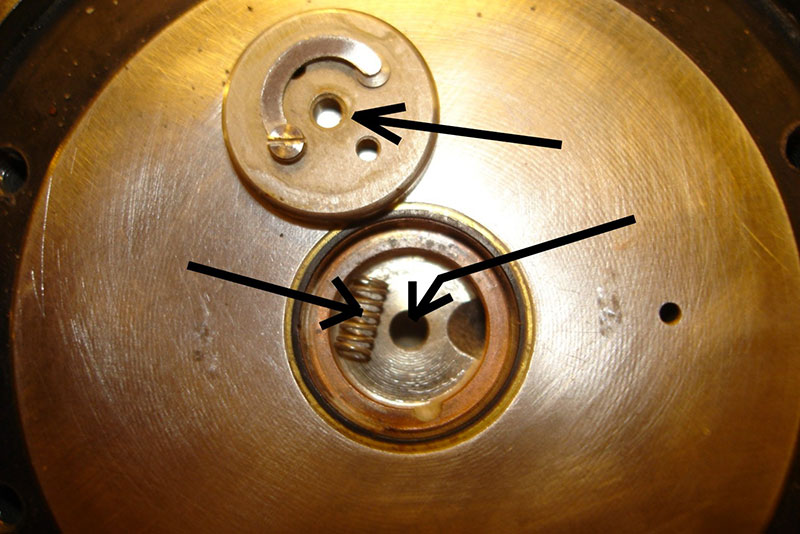

- Electrical reason of missing B

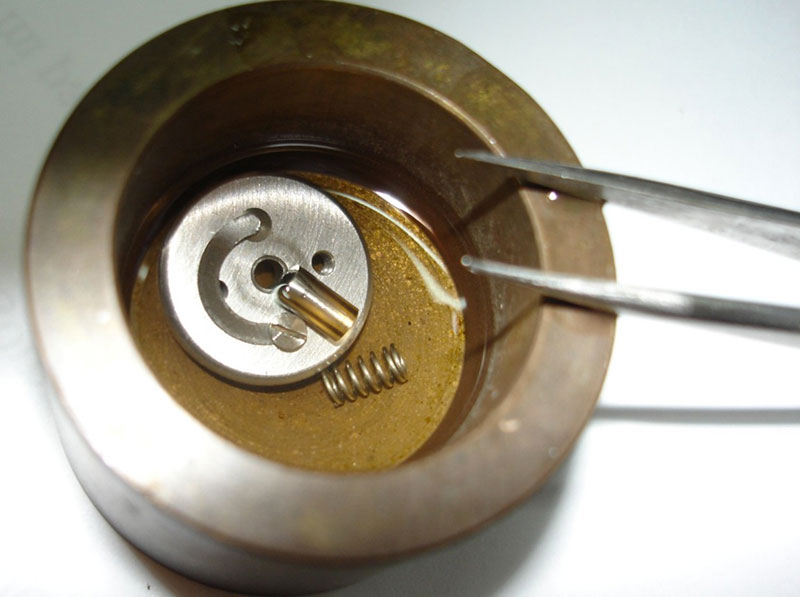

Dirt (or grains or piece of paper or cloth or else) in one of the 4 points evidenced by arrows in the picture. All these points must be perfectly clean to insure electrical continuity. You may use a solvent, a cloth, or fine sand paper. The final result must be that the 4 points are perfectly clean.

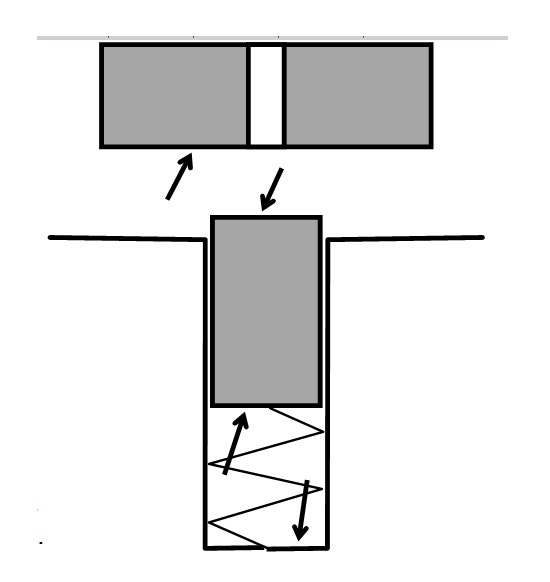

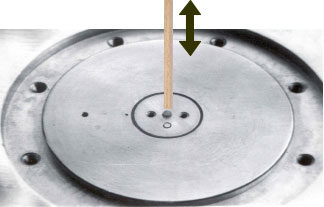

- Mechanical reason of missing B

The quartz cylinder must slide absolutely free in the 2.05 mm diameter hole of the Sensing Disk. Hence the 2.05 mm diameter hole must be perfectly clean. This can be done by rotating (manually) a 2.05 mm drill point, then inserting in the 2.05 mm hole and rotating a tapered wooden tooth-pick on the bottom face of the disk.

During all above operations use abundant compressed air with an air pistol.